Unlocking Efficiency with Cat5e Toolless Jacks in Your Projects: A Comprehensive Guide

Unlocking Efficiency with Cat5e Toolless Jacks in Your Projects

Table of Contents

- 1. Introduction to Cat5e Toolless Jacks

- 2. Understanding Cat5e Technology

- 3. Benefits of Using Cat5e Toolless Jacks

- 4. Installation Process of Cat5e Toolless Jacks

- 5. Best Practices for Using Cat5e Toolless Jacks

- 6. Common Issues and Solutions

- 7. Cost Analysis of Cat5e Toolless Jacks

- 8. FAQs About Cat5e Toolless Jacks

- 9. Conclusion

1. Introduction to Cat5e Toolless Jacks

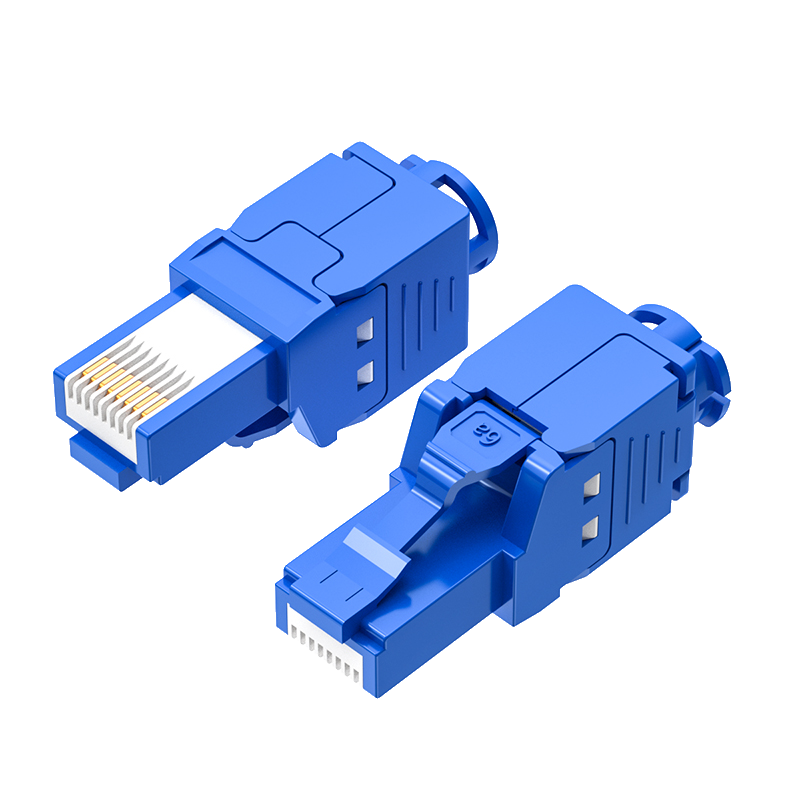

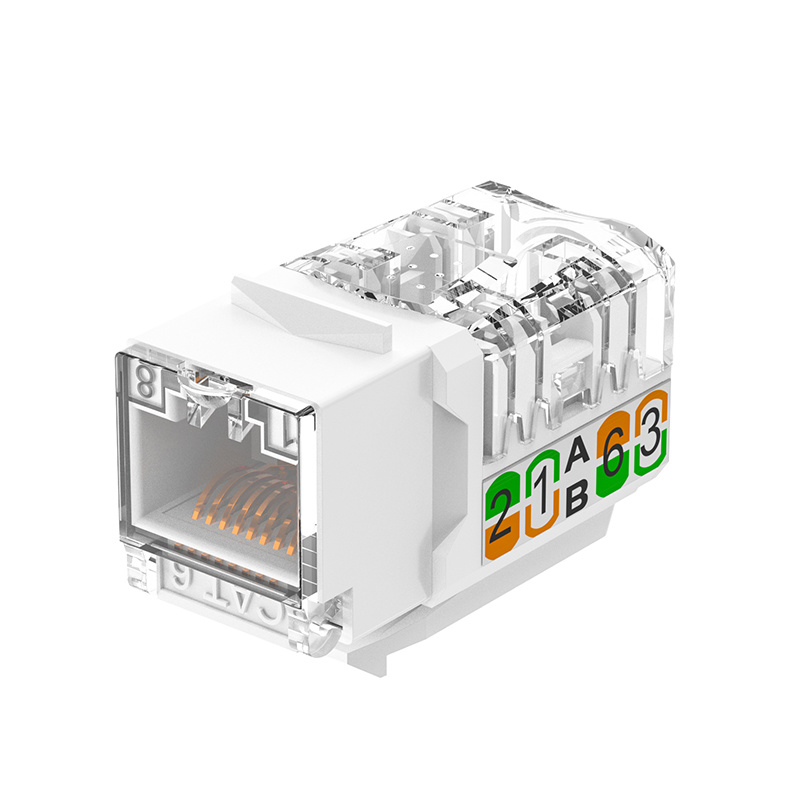

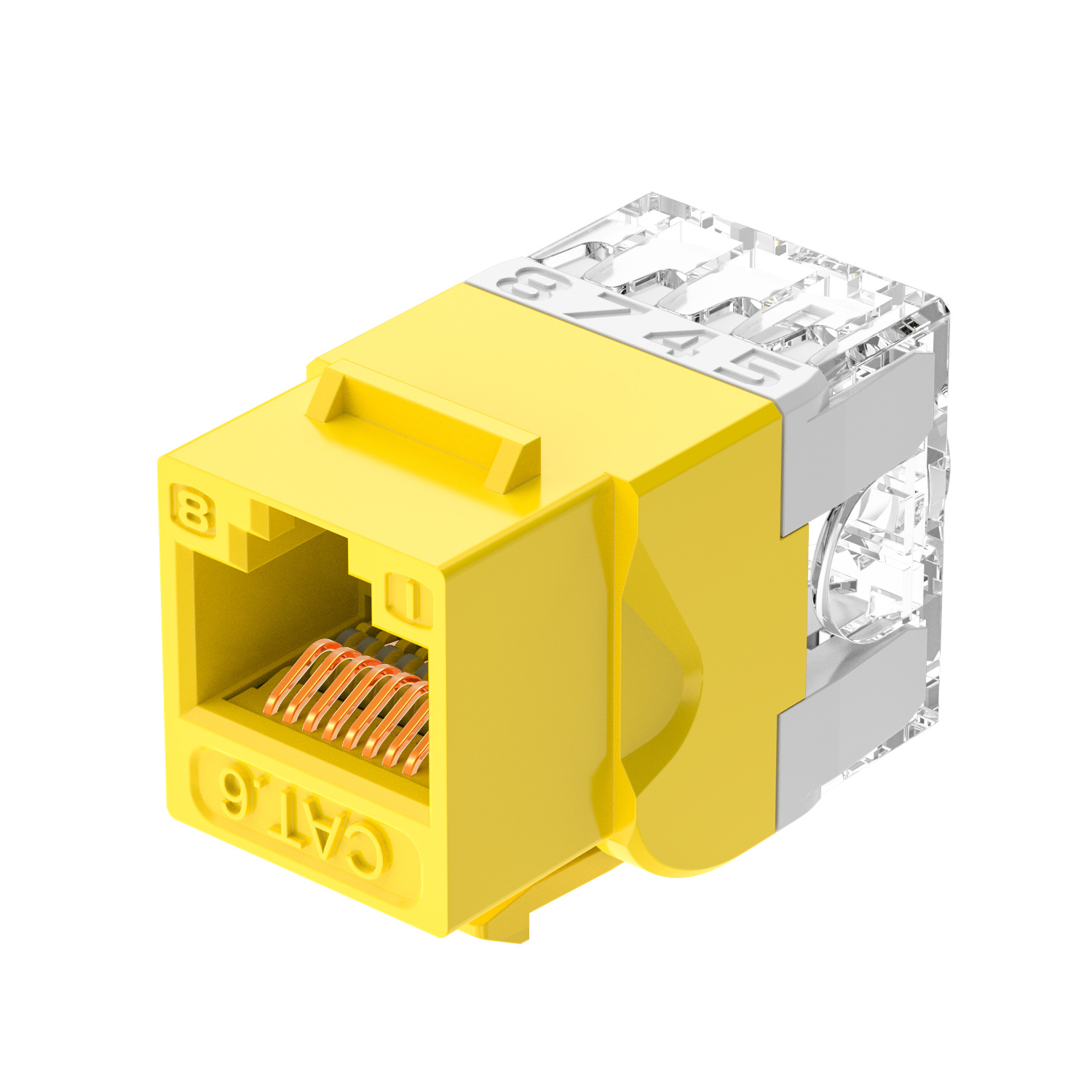

In an age where connectivity is essential, we find ourselves constantly seeking efficient solutions for our networking projects. One such solution is the **Cat5e Toolless Jack**, an innovative device that streamlines the process of connecting cables without the need for complex tools. These jacks are designed to enhance performance while simplifying installation, making them a preferred choice for both professionals and DIY enthusiasts.

2. Understanding Cat5e Technology

Cat5e, or Category 5 Enhanced, is a standard for Ethernet cables that supports data transmission speeds of up to 1 Gbps over distances of 100 meters. This technology improves upon the original Cat5 standard by reducing crosstalk and allowing for better performance in high-density networks.

The **Cat5e cables** consist of four twisted pairs of copper wires, each designed to minimize interference and support high-speed data transfer. Understanding the fundamentals of Cat5e technology is crucial for maximizing the benefits of toolless jacks.

3. Benefits of Using Cat5e Toolless Jacks

The advantages of utilizing **Cat5e Toolless Jacks** are manifold:

3.1. Simplified Installation

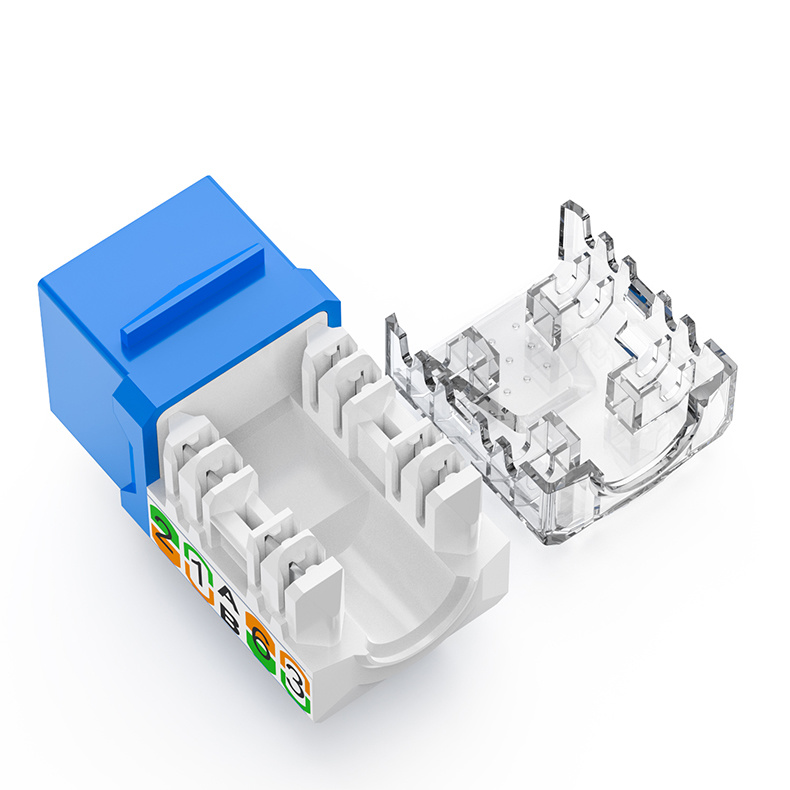

One of the most significant benefits is the ease of installation. Toolless jacks allow users to terminate cables quickly by simply inserting the wires into the jacks, eliminating the need for specialized tools. This not only saves time but also reduces the likelihood of installation errors.

3.2. Enhanced Performance

Toolless jacks are designed to maintain the integrity of the cable’s performance. They ensure that the twisted pairs remain intact, minimizing crosstalk and maximizing data integrity. As a result, users can expect optimal network performance.

3.3. Cost-Effective Solutions

Incorporating toolless jacks can lead to significant cost savings. The reduction in installation time means labor costs decrease, making projects more economical. Additionally, the durability of these jacks can lead to lower maintenance costs in the long run.

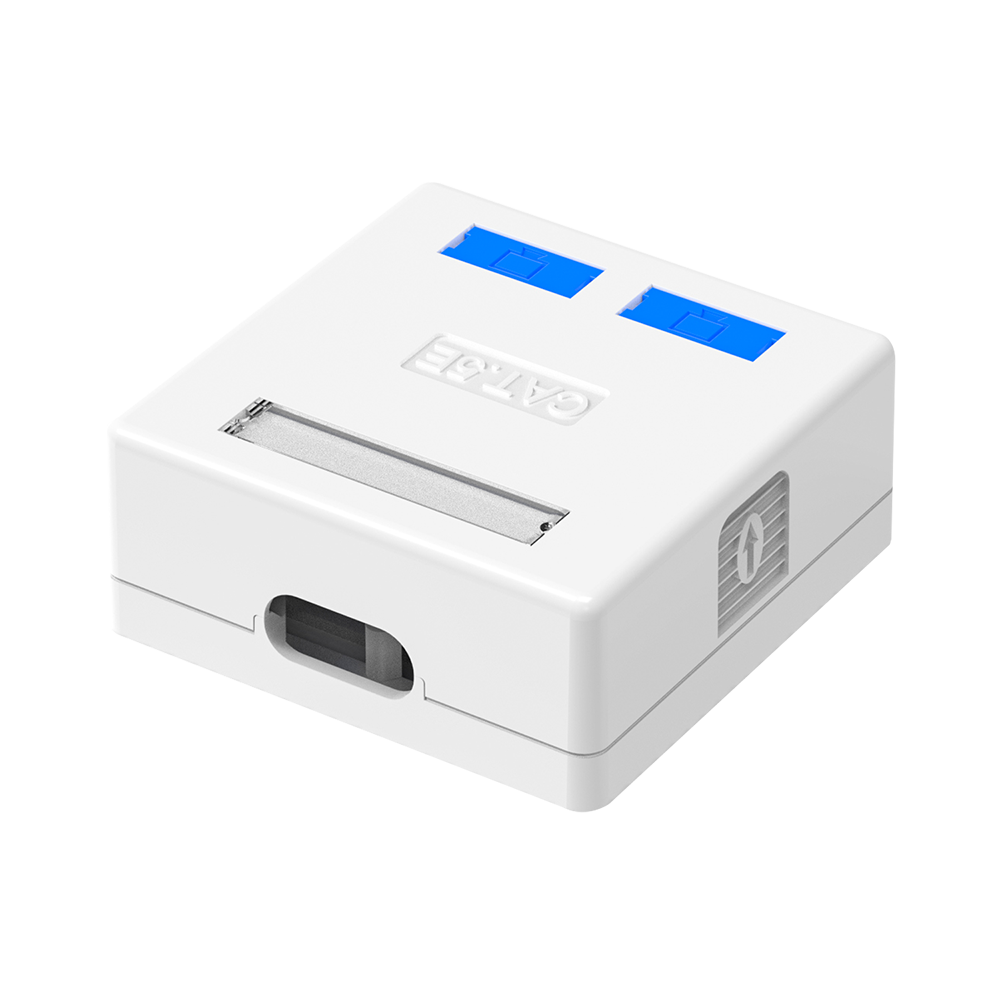

3.4. Versatility and Compatibility

Cat5e Toolless Jacks are versatile and compatible with various systems. Whether upgrading existing networks or installing new ones, these jacks can seamlessly integrate into a variety of setups.

4. Installation Process of Cat5e Toolless Jacks

Installing Cat5e Toolless Jacks is a straightforward process, but proper techniques ensure optimal performance. Here’s a step-by-step guide to facilitate the installation:

4.1. Gather Necessary Materials

Before starting, ensure you have the following materials:

- Cat5e cables

- Cat5e Toolless Jacks

- A wire stripper

- A cable tester

- Safety goggles and gloves

4.2. Cut the Cable to Length

Measure and cut the Cat5e cable to the desired length. It’s essential to leave some extra length to accommodate any adjustments.

4.3. Strip the Cable Jacket

Using a wire stripper, carefully strip about 1-2 inches of the outer jacket from the cable. Be cautious not to damage the inner pairs of wires.

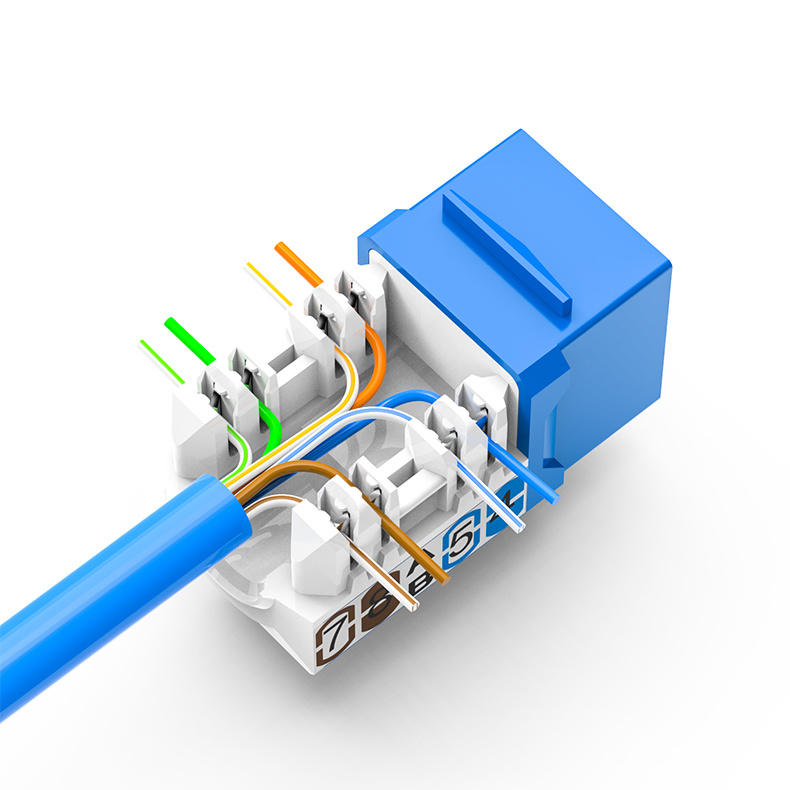

4.4. Untwist and Organize the Wires

Untwist each of the four pairs of wires and arrange them according to the T568A or T568B wiring standard. This arrangement is crucial for ensuring proper connectivity.

4.5. Insert Wires into the Toolless Jack

Insert the wires into the corresponding slots in the toolless jack. The design allows for easy insertion without needing any tools. Ensure each wire is fully seated to guarantee a solid connection.

4.6. Test the Connection

Once the wires are in place, use a cable tester to verify the connection. Testing ensures that there are no faults and that the network will perform as expected.

5. Best Practices for Using Cat5e Toolless Jacks

To maximize the benefits of Cat5e Toolless Jacks, adhere to the following best practices:

5.1. Maintain Proper Cable Management

Cable management is essential in any networking project. Ensure that cables are neatly organized to prevent tangling and reduce the risk of damage.

5.2. Follow Wiring Standards

Always adhere to T568A or T568B wiring standards during installation. Consistency in wiring ensures compatibility and performance.

5.3. Use Quality Components

Invest in high-quality Cat5e Toolless Jacks and cables. Quality components lead to better performance and longevity, reducing the need for replacements.

5.4. Regularly Test Your Network

Regularly testing your network can identify potential issues before they escalate. Use a cable tester after installation and periodically thereafter.

6. Common Issues and Solutions

While Cat5e Toolless Jacks are designed for ease of use, users may encounter some common issues:

6.1. Poor Connection

If the network is experiencing slow speeds or inconsistent connectivity, check to ensure that the wires are fully inserted into the jack and that they follow the correct wiring standard.

6.2. Interference

External interference can affect network performance. Ensure that cables are away from power lines and other potential sources of interference.

6.3. Physical Damage

Inspect the jacks periodically for any physical damage. If a jack is damaged, replace it immediately to maintain network integrity.

7. Cost Analysis of Cat5e Toolless Jacks

Understanding the cost implications of using Cat5e Toolless Jacks can aid in project budgeting. Here’s a breakdown of the potential costs involved:

7.1. Initial Investment

The upfront cost of **Cat5e Toolless Jacks** varies based on brand and quantity. Generally, they are priced competitively, with bulk purchases reducing costs further.

7.2. Labor Savings

One of the most significant savings comes from reduced labor costs. As installation is quicker and more straightforward, projects can often be completed in less time.

7.3. Long-term Durability

Investing in quality toolless jacks can lead to long-term savings. Durable components require less frequent replacement, reducing overall costs.

8. FAQs About Cat5e Toolless Jacks

8.1. What is a Cat5e Toolless Jack?

A Cat5e Toolless Jack is a type of connector that allows for quick and easy termination of Cat5e cables without the need for tools.

8.2. Are Cat5e Toolless Jacks compatible with other cable types?

While primarily designed for Cat5e cables, many toolless jacks can also support Cat6 cables, but always check compatibility specifications.

8.3. How do I know if my Cat5e Toolless Jack is installed correctly?

Using a cable tester after installation will confirm that the jack is installed correctly and that the network connection is functioning properly.

8.4. Can I reuse Cat5e Toolless Jacks?

Generally, toolless jacks are designed for single-use termination. Reusing them may compromise performance and reliability.

8.5. What are the benefits of using toolless jacks over traditional jacks?

Toolless jacks offer simplified installation, reduced labor costs, and enhanced performance by maintaining the integrity of the cable during termination.

9. Conclusion

In conclusion, **Cat5e Toolless Jacks** represent a transformative advancement in networking solutions, combining efficiency, performance, and cost-effectiveness. By simplifying the installation process and ensuring high-quality connections, these jacks empower both professionals and DIY enthusiasts to achieve reliable networking setups. Understanding their benefits, installation techniques, and best practices can help unlock the full potential of your networking projects. As technology continues to evolve, incorporating these innovative solutions will position you at the forefront of the electrical and networking industries.

Latest news & events

May 20,2025

Understanding the Installation Process of Terminating Cat6 Keystone Jacks: A Comprehensive Guide

Understanding the Installation Process of Terminating Cat6 Keystone Jacks Table of Contents 1. Introduction to Cat6 Keystone Jacks 2. Tools Required for the Installation Process 2.1 Essential Tools for Successful Installation 2.2 Optional Tools to Enhance Your Setup 3. Preparing the Cat6 Cables for Termination 3.1 Stripping the Cable Insulation 3.2 Arranging the Wires According to TIA Standards 4.

Learn moreMay 17,2025

Understanding Cat3 Telephone Keystone Jacks: A Key Component for Your Telecommunication Needs

The Cat3 Telephone Keystone Jack is a specialized connector designed for use in telecommunication wiring systems. It is primarily used for voice communication and is optimized for performance with standard telephone systems. Although it may not support high-speed data transmission like modern Ethernet cables, the Cat3 jack remains relevant in various applications, particularly where traditional te

Learn moreMay 14,2025

Why You Should Consider Upgrading to Cat5e FTP 180 Degree Toolless Jacks for Superior Connectivity

Why You Should Consider Upgrading to Cat5e FTP 180 Degree Toolless Jacks for Superior Connectivity In today’s fast-paced digital world, reliable and efficient networking solutions are paramount for both residential and commercial environments. As businesses and individuals increasingly depend on high-speed internet connectivity, the choice of networking components becomes critical. Among these com

Learn moreMay 11,2025

Exploring the Landscape of Cat5e Toolless Jack Manufacturers in China

In the ever-evolving electrical and cabling industry, Cat5e toolless jacks have emerged as essential components for efficient network connectivity. These devices enable quick and reliable connections without the need for specialized tools, making them especially advantageous for installers and technicians. When looking for Cat5e toolless jack companies in China, there are several factors industry

Learn more