Faceplate Transforming Modern Technology and Design

In the fast-evolving world of technology and consumer electronics, the faceplate has emerged as a subtle yet crucial component influencing both functionality and aesthetics. A faceplate, sometimes referred to as a front panel or cover plate, is typically the external layer or shell that encases a device, interface, or machine, providing protection while offering a sleek, visually appealing surface. While often overlooked by end-users, the faceplate plays a significant role in the overall performance, durability, and user experience of a product.

Traditionally, faceplates were primarily used in industrial equipment and household appliances to protect internal components from dust, moisture, and accidental damage. Materials such as metal, plastic, and glass were commonly employed due to their durability and ease of manufacturing. However, the evolution of technology has expanded the role of faceplates beyond simple protective barriers. Today, they are designed not only to safeguard delicate electronics but also to enhance user interaction and reinforce brand identity through visual design.

One of the most visible applications of faceplates is in consumer electronics, including smartphones, tablets, gaming consoles, and home automation devices. In these contexts, faceplates often combine functionality with design sophistication. For instance, smartphone manufacturers are constantly innovating with materials and finishes to create scratch-resistant, fingerprint-proof, and aesthetically pleasing faceplates. High-end devices may incorporate glass or ceramic faceplates, which not only offer superior durability but also contribute to a premium tactile experience. Meanwhile, mid-range products might utilize polycarbonate or reinforced plastic, balancing affordability with adequate protection.

Beyond aesthetics, faceplates are critical in enhancing device ergonomics and user safety. In industrial settings, custom faceplates can include touch interfaces, control buttons, or status indicators, allowing operators to interact with machinery efficiently. Advanced manufacturing techniques, including CNC machining, injection molding, and laser etching, have enabled the production of highly precise faceplates with complex shapes and functional cutouts, supporting both mechanical and electronic integration. These innovations are particularly important in industries such as automotive, aerospace, and medical equipment, where precision, durability, and compliance with safety standards are paramount.

The market demand for customizable faceplates has also surged. Businesses and consumers increasingly seek products that reflect personal style, branding, or functional requirements. Custom faceplates allow manufacturers to differentiate their offerings in a competitive market while meeting specific client needs. For example, in the gaming industry, companies often offer replaceable faceplates for consoles or controllers, enabling users to personalize color schemes, textures, and materials. Similarly, in home automation and smart building systems, modular faceplates can be tailored to integrate seamlessly with wall designs, enhancing both aesthetics and functionality.

Innovation in materials has further expanded the capabilities of faceplates. Advanced composites, aluminum alloys, tempered glass, and antimicrobial coatings are becoming more common, offering enhanced strength, longevity, and hygiene. The integration of touch-sensitive panels, LED indicators, and wireless charging capabilities within faceplates demonstrates the convergence of design, technology, and user experience. These advancements indicate that faceplates are no longer passive components; they are active contributors to the overall product ecosystem.

Sustainability has emerged as another critical factor in faceplate design and manufacturing. As consumer awareness of environmental impact grows, manufacturers are exploring recyclable plastics, eco-friendly coatings, and energy-efficient production processes. By adopting sustainable materials and responsible manufacturing practices, companies can reduce the carbon footprint associated with faceplate production, aligning with global trends toward greener electronics and equipment.

Market analysis indicates a steady growth trajectory for the faceplate industry. Increasing demand from electronics, automotive, home appliances, and industrial machinery sectors is driving innovation in materials, manufacturing methods, and customization. Asia-Pacific, North America, and Europe remain key regions, with manufacturers leveraging advanced technologies to meet the diverse demands of global markets. Notably, the rise of smart homes and IoT-enabled devices has further accelerated the adoption of innovative faceplate designs, emphasizing aesthetics, interactivity, and durability.

In conclusion, the faceplate represents more than a protective shell—it is an integral part of modern product design, bridging the gap between technology and user experience. From smartphones to industrial control panels, the evolution of faceplates reflects broader trends in materials science, ergonomics, and consumer preferences. As technology continues to advance, the faceplate will remain a critical element in shaping the functionality, appearance, and sustainability of modern devices, highlighting its indispensable role in the design and engineering of tomorrow's products.

Latest news & events

Jan 27,2026

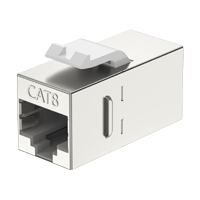

Keystone Jack: Building the Foundation of Modern Network Connectivity

Keystone Jack ensures stable, high-speed data connections, offering modular design and easy installation for networks

Learn moreJan 19,2026

HY‑CONNECT’s New Ethernet Keystone Jack HKJ‑802FM‑LM Boosts Cabling Flexibility and Performance

Ethernet Keystone Jack HKJ‑802FM‑LM for reliable, high-speed network connections in offices, data centers, and smart homes

Learn moreJan 04,2026

RJ45 Connectors The Backbone of Modern Networking Infrastructure

RJ45 connectors provide reliable Ethernet connections, supporting high-speed data transmission for networks and devices

Learn moreDec 29,2025

Faceplate Socket: Enhancing Modern Electrical Installations with Safety and Style

Faceplate socket provides safe, convenient electrical access with sleek design, surge protection, and USB or multimedia options

Learn more